I received a question from Jeremy in Texas about why we use DOM tubing and what DOM actually is. Really, it’s a great question, because you hear “DOM” and to most people have zero idea what DOM stands for. So here we go, and I promise minimal cut and paste from external sites.

D.O.M is an acronym for “drawn over mandrel”. DOM tubing is not a special material per se, but more of a description of the process on how the tubing is made.

Before I launch into more, I am going to give you a quick breakdown in the least technical sense possible to grasp a basic understanding of some metal working info. Please metal specialist, don’t judge, I don’t exactly have a degree in this, and I am trying to explain it so most people get it. The question got a lot more in depth than I intended so I had to do some research to be able to properly explain the differences.

Hot Rolled Steel: Steel that has been processed above the recrystallization point

Cold Rolled Steel: Processed below the recrystallization point, usually has higher tensile strength, uniformity, and tolerances

Recrystallization point: Where steel softens, approximately 1000 degrees Fahrenheit (varies based on the amount of carbon in the alloy)

Melting Point: Where steel becomes a liquid, approximately 2500 degrees Fahrenheit

Alloy: A mixture of 2 or more metals

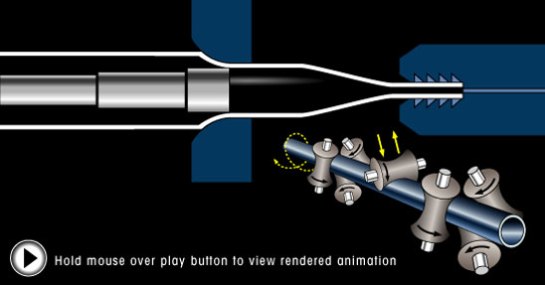

Mandrel: a tool used to shape metal….

Weld: putting 2 pieces of metal together by heating the surface to melting, so they fuse together

Wall: the thickness of the tubing (not the diameter)

Tensile Strength: the resistance of material to break under tension

Electric resistance welding: A type of welding that uses more than one process to form a forged weld (which is created by heat and pressure) which is like a long, continuous spot weld.

Dies (metal working) a tool used to form metal that gives consistent results (a pattern in a way)

Ok so now that you have a metallurgist vocabulary (in the least technical sense possible) let’s move on to explaining what DOM tubing is and a few common misconceptions.

ERW (Electric Resistance Welded) steel tubing is created starting with either a hot or cold rolled flat strip of steel. It is then formed into a tube and welded. Not as strong as other steel tubing, but also less costly.

Seamless Steel Tubing: Alright, so this is where a lot of people are misinformed. Many people think that DOM and seamless are interchangeable, and in fact the same thing. WRONG. Seamless tubing is quite the process and is pretty darn expensive to make. The simplest way to explain it is almost like it is the “billet” version of metal. Or course there are variations of this (hot and cold formed), but the basic process is such. You start with a block of metal and it is pierced with a special tool and incredible pressure down the middle to form the initial tube shape. Then it proceeds to an elongator of rollers and an internal mandrel to further form to the dimensions needed. Next, is a reducing mill where it makes the diameter closer to the needed size. At this juncture it is actually oval shaped. Then, lastly, it is off to the rotary sizer, where it is made round again and finished to its final size.

Seamless tubing is generally the strongest, as well as the most costly of steel tubing, and is rarely used in automotive applications. Which brings me to the middle and what we use (as well as most off road applications)

DOM Tubing: Firstly, most DOM tubing is a steel/carbon alloy of 1020, which means it is .20% carbon and 99.80%steel. It might not seem significant, but it is.

As I mentioned before, DOM is the process by which the tubing is made, not the materials. DOM is actually ERW tubing with an extra step. Most people don’t realize that though, because you can’t see the weld nor can you feel it, which makes it appear seamless. That extra step is what makes this happen.

It starts as a coil of steel with a premeasured slit for the proper size. Then it is cold formed and passes through an electric resistance welder. From there it is cut for further processing. After it is cut is drawn through one or more dies and over a mandrel which creates a uniform look as well as getting the diameter and walls to the proper size.

In summary:

ERW tubing is the least expensive with the least strength

DOM tubing is in the middle

Seamless is the most

Prices vary day to day because the price of steel fluxuates significantly, however the tensile strength is the same. SO (obviously some variations because hot and cold formed/rolled process creates different strengths, as well as sources having conflicting info, so we will go with a give or take)

In 1020 alloy with a .120 wall (PSI)

ERW has a tensile strength of 45,000 lbs.

DOM has a tensile strength of 80,000 lbs.

Seamless has a tensile strength 87,000

Another reason the DOM is nice, is that on some of the welded tubing when have enough weight/pressure, the weld will give and you split the metal, which, my friends is no bueno and not a fun repair!

Now that I am done with this post, I know way more than I wanted to, and regret starting this project. It was much more technical than I was aiming for on a weekend. Hopefully I answered your question and gave everyone a mini education 😀 Until tomorrow!